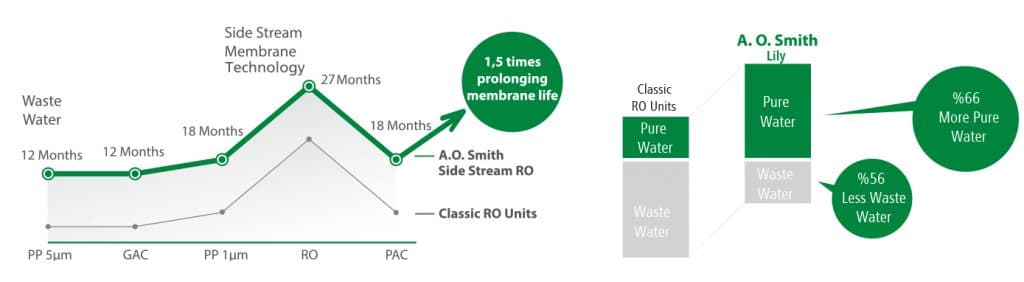

In the reverse osmosis system the water passes through the pores on membranes by means of high pressure. The majority of the materials in water cannot pass through these pores during this procedure and the water is drained as concentrated water. With this procedure, better water quality can be achieved than through filtration systems. The frames of reverse osmosis systems can be made of stainless or epoxy-protected carbon steel. With reverse osmosis membranes all dissolved brine, inorganic molecules and organic molecules with high molecular weight are eliminated. You can obtain purified water from various raw water sources (wells, sea, rivers, etc.) by performing a filtration of the water’s molecular structure at a rate of 90-99.5%. A.O. Smith offers specific solutions for your needs in domestic and industrial area

Reverse Osmosis System Usage Areas

- Drinking water production

- Non-alcoholic beer production

- Juice and beverage industry

- Power plants

- Chemical industry

- Pharmaceutical industry

- Municipal and service water production from sea water

- Custom tailored solutions for obtaining pure water for industrial applications

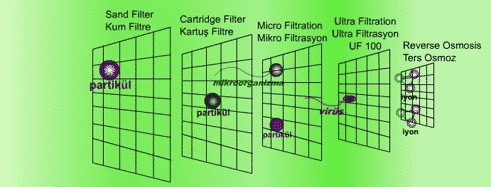

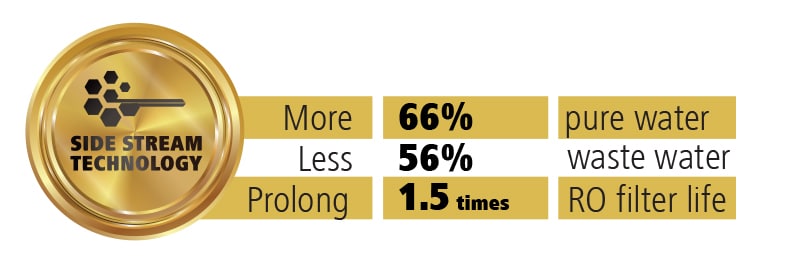

Side Stream RO Membrane Technology

Side Stream R.O. Membrane Technology is a special innovation by A.O.Smith. Side Stream R.O. Membrane use patented MLSB Screw-type Technology.

MLSB (multi-leaves single-bag) membrane has vertical inflow and concentrate water direction; longer and narrower inflow passage thus app. 2,8 times higher surface flow rate. Higher flow rate can reinforce the effect of surface flush, of R.O. membrane, reduce the rate of concentration polarization, blockage, scale formation, waste water discharge, and increase the salt rejection rate.

The Side Stream R.O. membrane increases the recovery rate to around 50%, compared to 25% for the regular residential R.O. membrane, and waste water volume is reduced by 56%.

Combined with MLSB Screw-type Technology, Side Stream R.O. Membrane creates the world’s highest utilization rate for residential membranes, reaching 85-90% compared to only 70% for traditional membranes.

With patented full flush function, it completely solves the traditional water purifier problem of having no way for the concentrate water to flush out of the membrane when the tank is full, leading to membrane scale and pollution problems. The optimal flushing design reduces flushing discharge by 50% and extends the service life of the membrane by 1,5 times.

Advantages

- Less Waste Water: It can reduce 56% waste water, energy saving,

- en vironmental protection, enjoy low carbon living;

- More Pure Water: It can increase 66% pure water, more efficient and

- highest utilization;

- High Salt Rejection: Its salt rejection can be more than 95%, which is the top level of residential membrane;

- Long Life: By less concentration polarization, it has a low risk contamination and long life span app. ;

- Reliable Structure: It has water hammer and attack protection, mistakeproof design to prevent wrong installation;

- Better Sealing: Two o-ring design, completely leak tight, insure pure water quality;

- Compact Size: 10% smaller, more compact, lighter design.

MBR Technology

A membrane bioreactor (MBR) is a combination of biological reactors and membrane technology. After the biological treatment, the separation procedure can be performed by using the ultrafiltration (UF) or microfiltration (MF) membranes instead of settling basin. Nitrogen elimination can also be performed with the membrane bioreactor (MBR). These systems which eliminate a set of the disadvantages of conventional treatment methods occupy an important position among advanced treatment technologies of the future. Compared to conventional biological treatment processes, the MBR treatment process has a high chemical oxygen need (CON) removal efficiency for waste with low biological degradability. Additionally, MBR systems occupy much less space than conventional systems. Especially along with high treatment efficiency in cases where MBR technique is used, not only is there no need for a settling basin in biological treatment, but also the aeration basin can be designed with a size equal to one third of the size in conventional methods and thus, over 70% saving is achieved across a whole settlement and construction area. With the technique that can be applied as an immersion membrane filter operating at negative pressure or filters operating at positive pressure, waste water in biological treatment through the bioreactor is passed through the filter texture with pores 0.2 microns in size. While all solid matter larger than this is held, waste water is recovered almost without any solid matter or microorganisms. Waste that accumulates on the filter texture of the membrane is physically and chemically eliminated from the filter by periodical backwashing performed with purified water and the chemical cleaning processes. This waste is taken into the biological treatment process once again.

MBR Usage Areas

- Gray water treatment systems

- Advanced treatment of domestic and industrial waste water

- Treatment of water with high pollution

- In cases where there are limits for discharging, especially into water basins

- Obtaining irrigation water from waste water and recovery projects

- Projects in which the settlement area is inadequate for conventional systems

- Projects in which a waste water treatment facility is inadequate in capacity increases Recovery of waste water in processes with high water consumption

Nanofiltration Technology

The nanofiltration-membrane pore size is 0.001 micron and the applied pressure is higher. This system is capable of treating all bacterias, viruses and cysts. Nanofiltration also removes alkalinity from the water. Therefore, the water obtained can have a corrosive structure. Nanofiltration membranes are also known as softener membranes given that nanofiltration also separates the minerals causing hardness in water. NF can be used as a replacement for demineralization, color removal, COD removal, waste water recovery and desalination.

Nanofiltration System Usage Areas

- Food industry

- Ground water

- Surface water

- Clean water supply

Ultrafiltration Technology

Ultrafiltration systems, one of the membrane solutions with significant advantages in the treatment of spring and drinking water, ensures a high efficiency filtration in the elimination of turbidity, bacteria, colloid, silt, viruses and organic substances in your water without requiring the use of any chemical materials due to membranes with a pore diameter of 0.01 microns.

Ultrafiltration System Usage Areas

- Food industry

- Carwash and washhouse water recovery

- Chemicals and waste water

- Performance of reverse osmosis pre-treatment

- Water requiring precise filtration

- Open and closed water circuits

- Industrial solid and liquid separation purification processes

- Producing purified water from micro-organisms